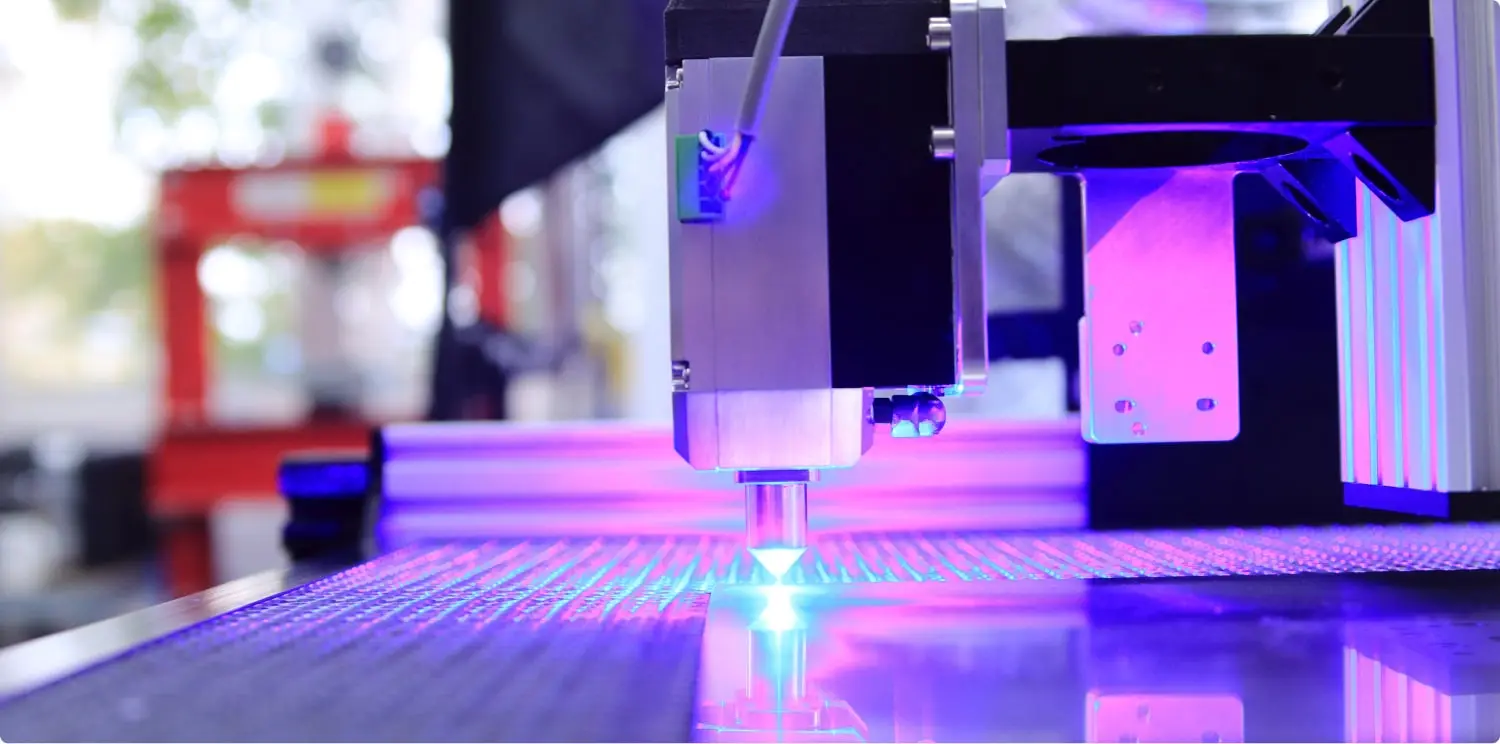

Computer Numerical Control (CNC) Machining and Precision Grinding

Our CNC machining process uses a computer-controlled robot to craft precise and detailed parts from materials such as metals and plastic. A computer program follows a digital blueprint to instruct our CNC machinery to use cutting, drilling, milling, punching, and turning, to create custom components, ensuring precision and accuracy of up to 0.01mm.

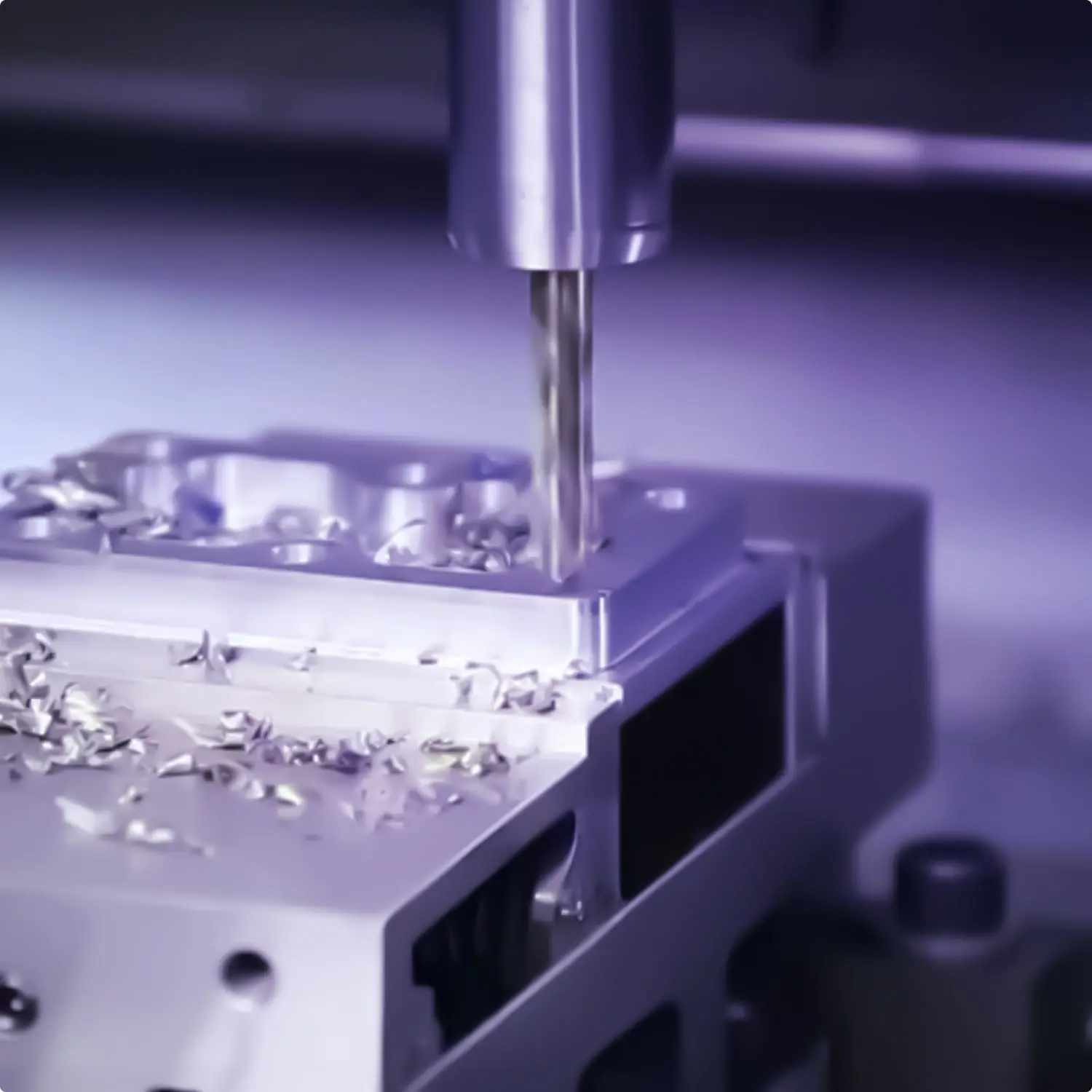

CNC

Milling

Our CNC milling service uses a robotic sculptor that can carve precise shapes and cuts out of materials such as metals and plastic. It leverages a computer program to manoeuvre a cutting tool mounted on a rotating spindle to remove specific portions of the material, creating detailed and accurate parts with a precision of up to 0.01mm.

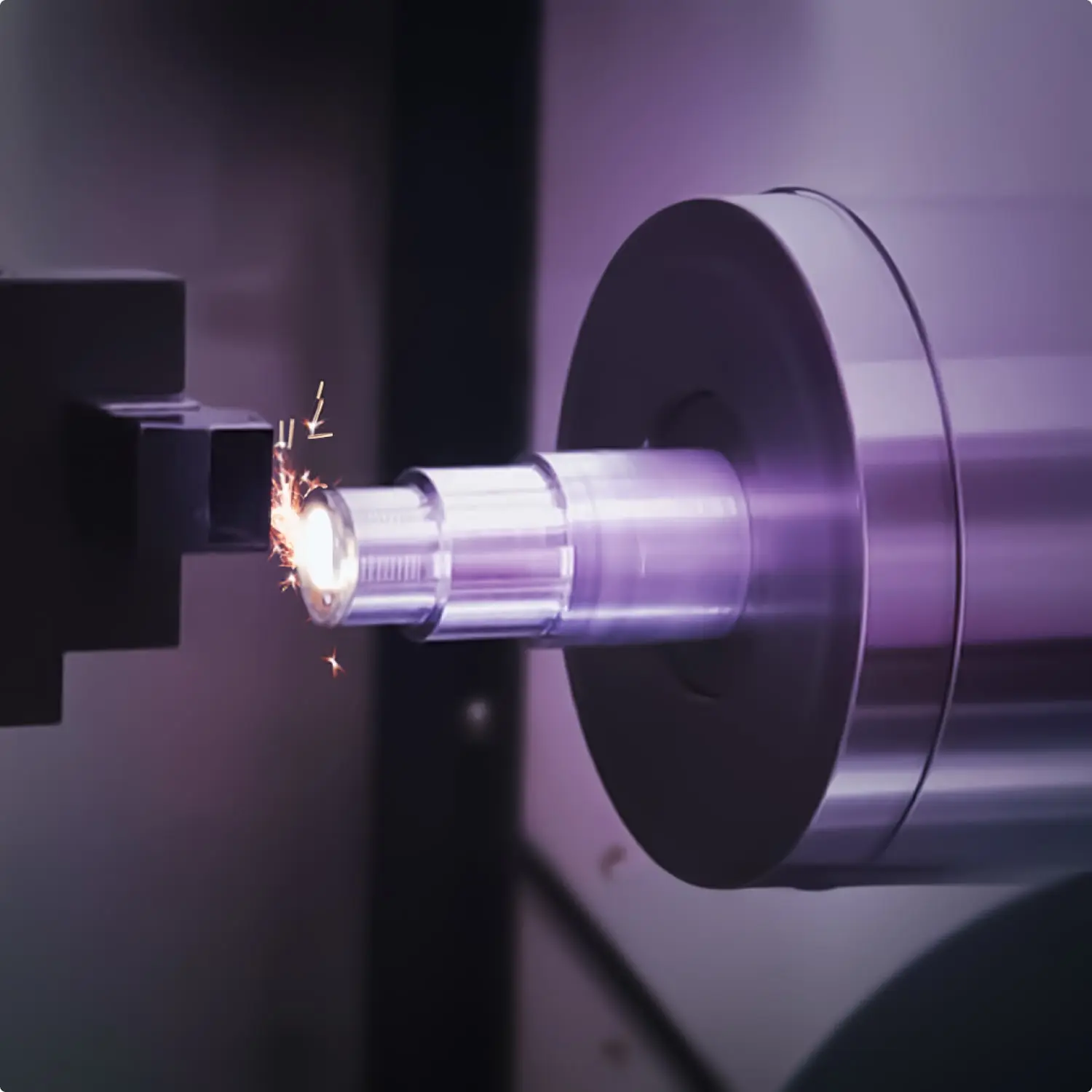

CNC

Turning

Our CNC turning service is a precise and automated way of making round-shaped parts. It uses a smart lathe that spins and shapes materials such as metals and plastic, into cylindrical parts. It leverages a computer program to precisely cut and form the material to create components such as bolts or fittings.

Precision

grinding

Our precision grinding service uses a grinding wheel to finely shape and smooth metals. Our machine is able to grind and polish metal surfaces with precision of up to 0.01mm, ensuring smooth and precisely shaped components for both technical and aesthetic purposes.

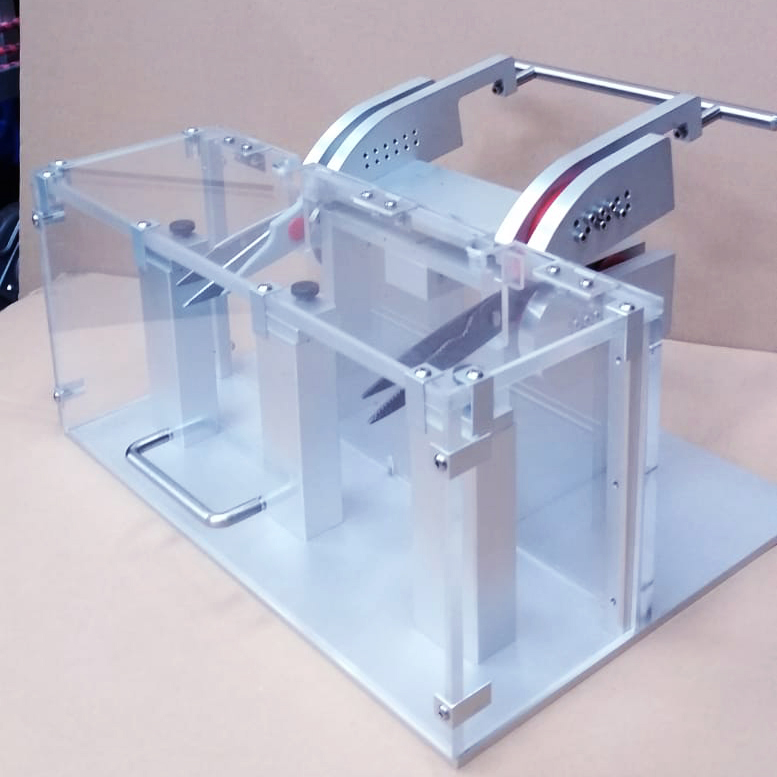

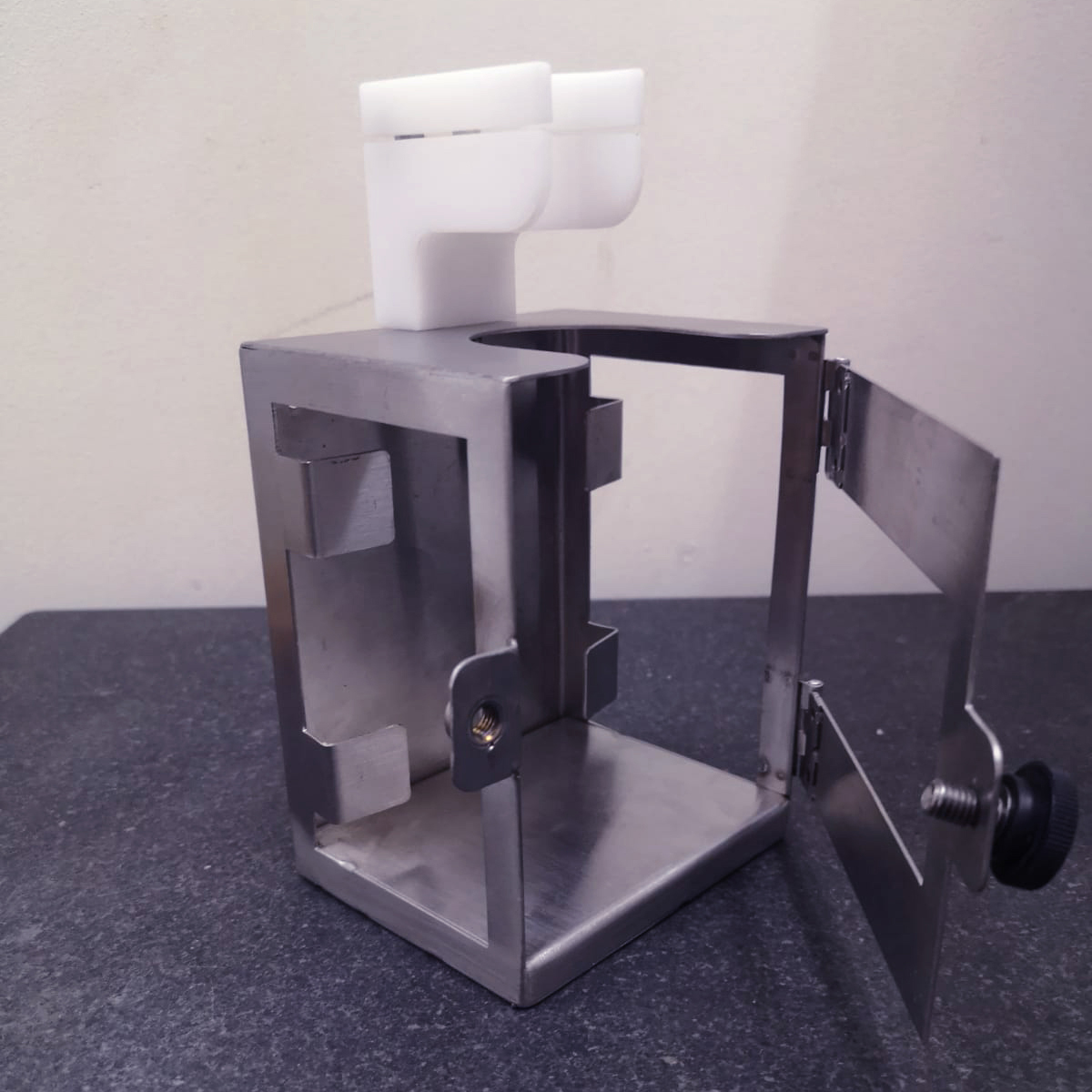

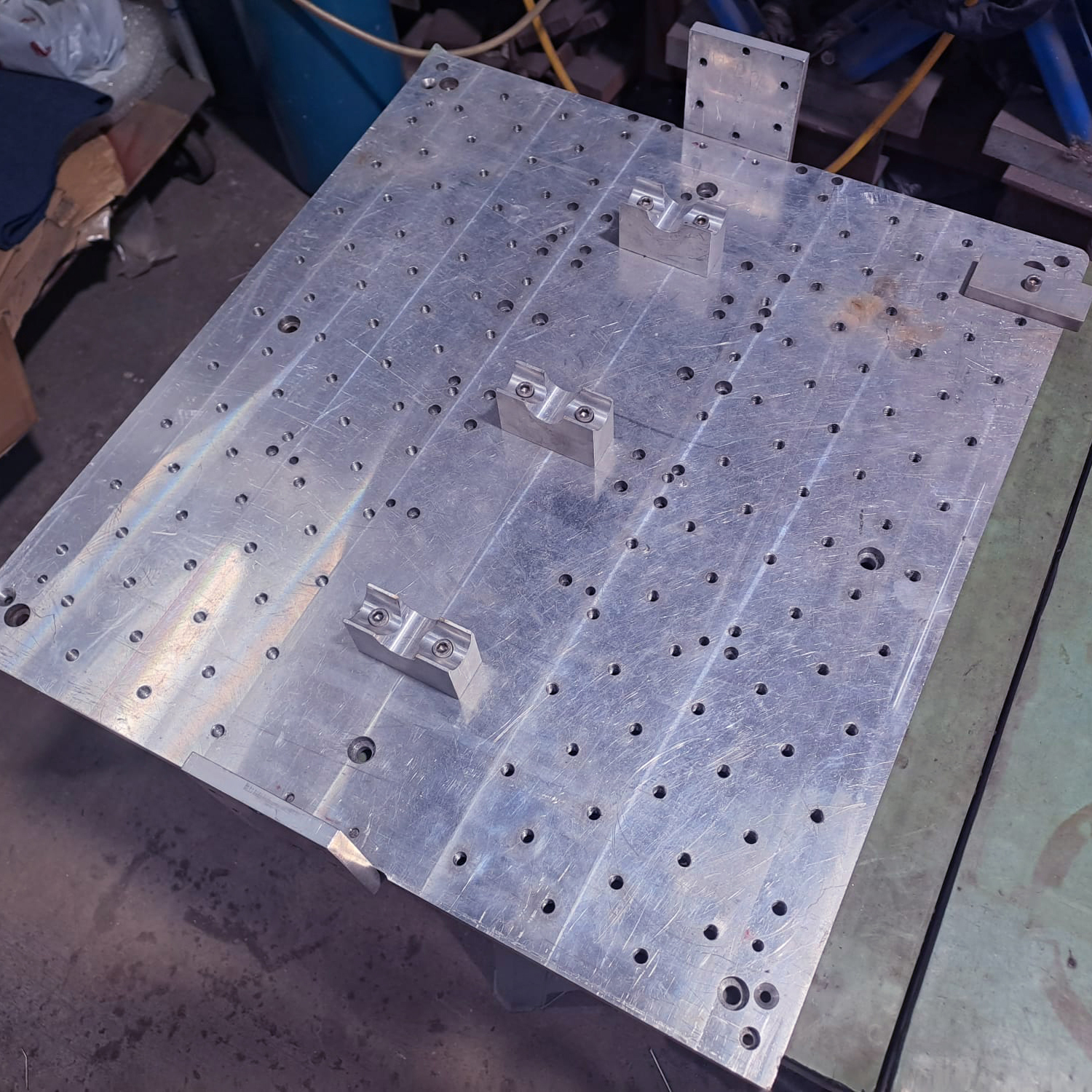

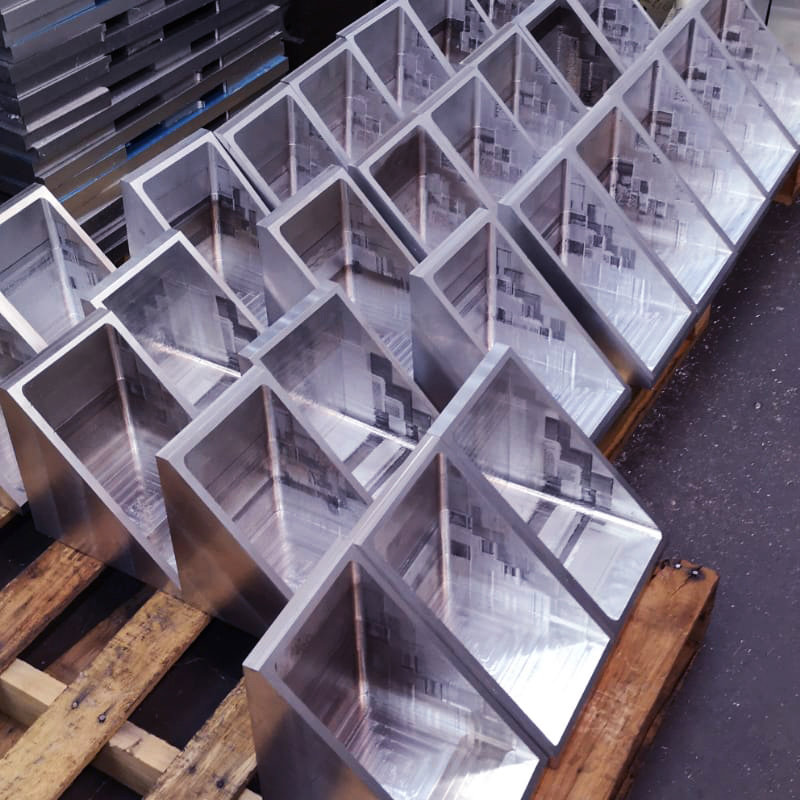

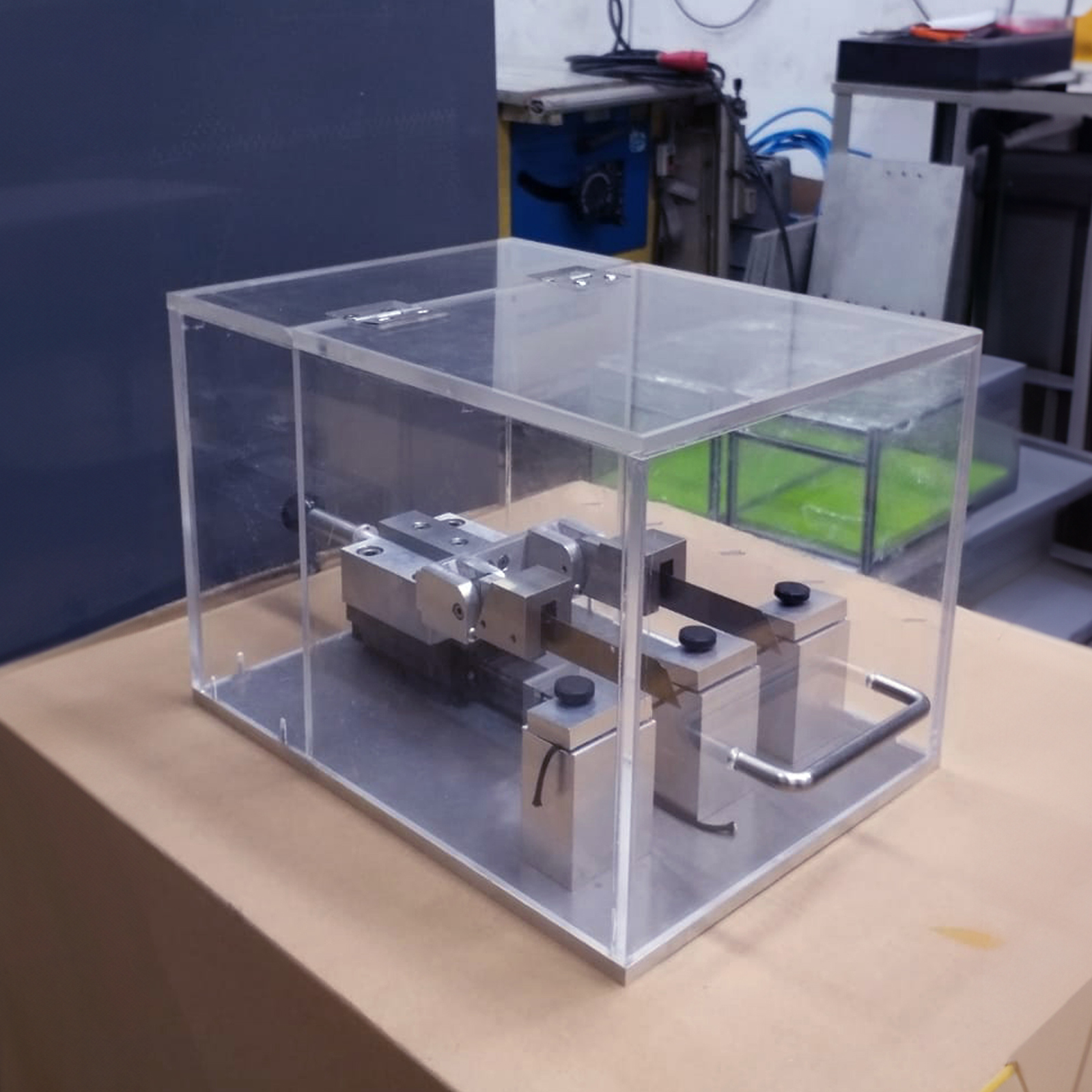

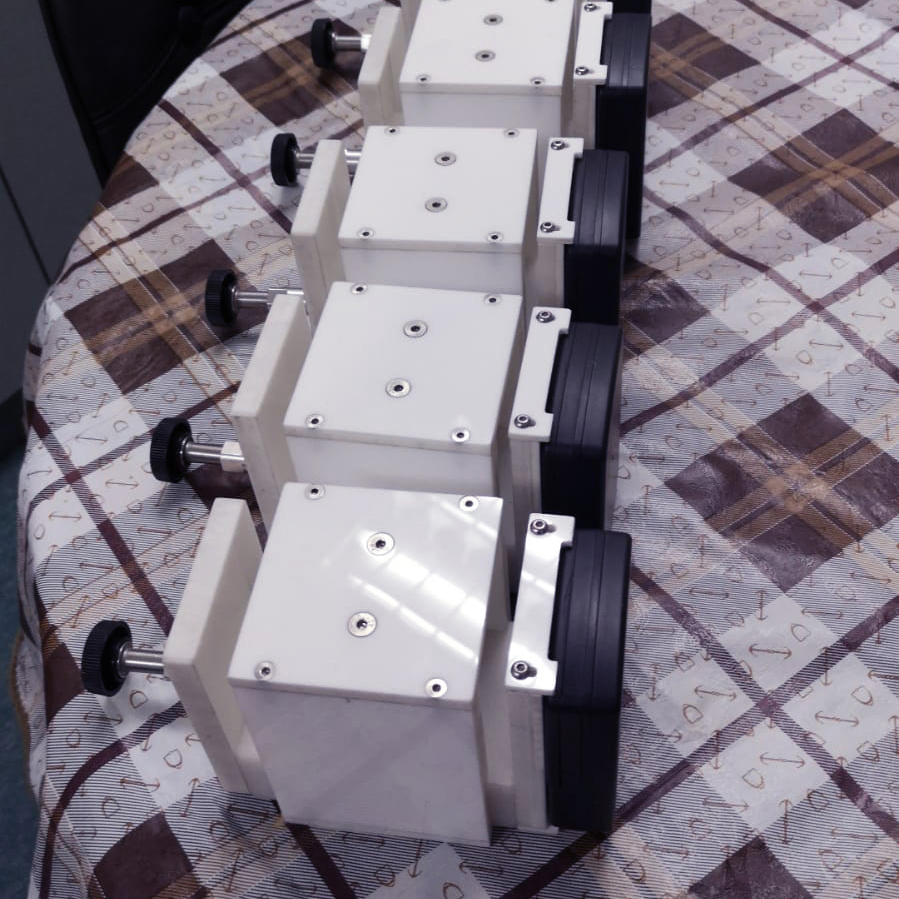

CNC Projects

Still not sure what we can offer? Check out some of the projects we have delivered to satisfied customers.